Into the famous Enterprise-Sasol not all pseudo-thin hydrobauxite is called "SB" powder

2024-10-26

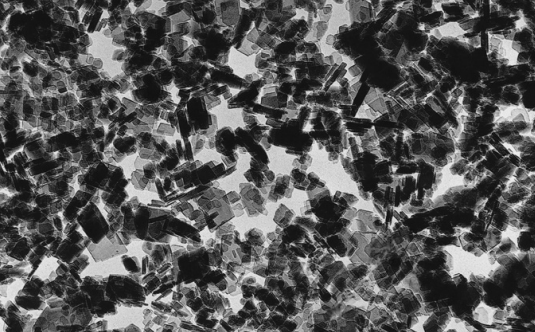

In the petrochemical industry, with the trend of heavier and poorer crude oil quality, blending heavy oil and residual oil into the feedstock for catalytic cracking has become a commonly adopted processing method. It necessitates the enhancement of the cracking capacity of fluid catalytic cracking (FCC) catalysts towards large molecular compounds, thereby requiring the catalyst supports to possess a high pore volume, which facilitates the diffusion of large molecular compounds into the interior of the catalyst particles, and a large specific surface area, which is conducive to the dispersion of active metals. Pseudo-boehmite (AlOOH·nH2O, n=0.08-0.62), as a precursor of catalyst supports, its crystallinity, particle size, aggregation state, and morphology significantly impact or even determine the performance of the supports.

Various alumina catalyst supports

Origin of "SB" Powder

As a global chemicals and energy company, Sasol is well known for its high-purity, highly dispersed, and customized Boehmite products tailored to specific pore sizes, particle sizes, and specific surface areas. In the domestic petrochemical catalysis industry, its pseudo-boehmite products are habitually referred to as "SB Powder" (Sasol Boehmites), a name derived from the company's name and used as a substitute for generic products, undoubtedly reflecting Sasol's preeminent position in the industry.

In addition to the DISPERAL branded pseudo-boehmite produced at its German factory, Sasol's Inorganic Chemicals Division also offers aluminum hydroxide under the DISPAL brand manufactured at its US facility. For the purpose of this article, and in accordance with domestic industry practices, "SB Powder" will be specifically referred to as pseudo-boehmite.

Production of "SB" Powder

Sasol employs the alkoxide hydrolysis method as its primary processing route for producing "SB" powder. The alumina used in this process can either be a by-product from the Ziegler process for olefin production or can be produced as a main product. The alkoxide hydrolysis method falls under the category of sol-gel methods, where metal alkoxides, compounds in which the hydrogen atoms of organic alcohol hydroxyl groups are replaced by metals, are used to prepare materials such as alumina and zirconia. Public literature describes the production of alumina through this method, which typically uses aluminum isopropoxide as the raw material. Hydrolysis of aluminum isopropoxide can directly yield alumina hydrates. While this method offers mild reaction conditions, minimal introduction of impurities, and high purity products, the high cost of alkoxides leads to increased production costs. Furthermore, the organic solvents generated during the reaction can cause a certain degree of environmental pollution.

Sasol's Optimization

Sasol has undoubtedly refined this process, implementing various optimizations such as controlling the nitric acid gelation time (NAG, the time required for the sol to reach a certain viscosity) during production to customize the particle size distribution. By adjusting the calcination temperature and time, Sasol is able to regulate the crystalline phase, specific surface area, and porosity. Additionally, the recovery of higher alcohols is achieved to reduce costs and minimize pollution. Sasol's testing and analysis protocols include:

- Trace element analysis using Inductively Coupled Plasma Optical Emission Spectrometry (ICP), Atomic Emission Spectrometry, and X-ray Fluorescence Spectrometry.

- Crystal phase analysis with X-ray Diffraction (XRD).

- Particle size measurement utilizing Particle Size Analyzers and Air Jet Sieves.

- Specific surface area determination through BET Surface Area Analyzers.

- Porosity analysis with Nitrogen Adsorption Instruments.

- Differential Scanning Calorimetry (DSC) for measuring reaction rates, crystallization rates, and various thermodynamic and kinetic parameters.

- Nitric acid gelation tests to measure the viscosity of dispersions.

Furthermore, Sasol demonstrates German-style professionalism and meticulousness in transportation and storage. Given the relatively low Mohs hardness (3.5-4.0) of hydrated alumina products, their susceptibility to moisture absorption and contamination, Sasol recommends the use of aluminum or polypropylene-lined carbon steel for related equipment. Additionally, pneumatic conveying is strictly operated at specific flow rates.

Other products

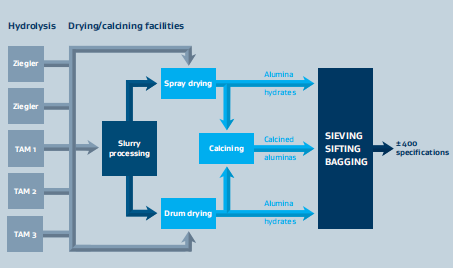

Sasol Alumina-Based Product Manufacturing Process flow chart

In addition to producing "SB" powder through its proprietary production process, Sasol also offers a wide range of high-purity and ultra-high-purity synthetic specialty alumina and related products, such as silica-alumina, hydrotalcite, and spinel, with a portfolio of over 400 customized product specifications.

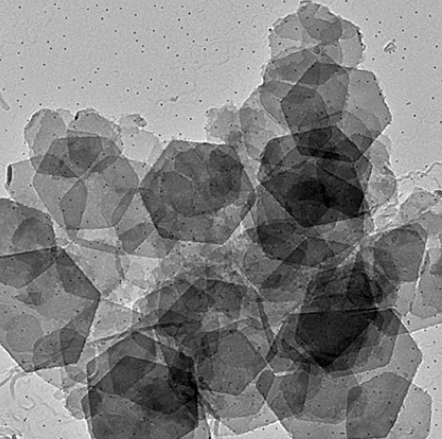

For example, the hydrotalcite (an aluminum-magnesium compound) developed based on its alkoxide hydrolysis technology is obtained through the hydrolysis of mixed alkoxides, with an Al/Mg ratio that can vary within a wide range. As a catalyst support material, it is suitable for applications requiring lower surface acidity than that achieved with pure alumina.

hydrotalcit

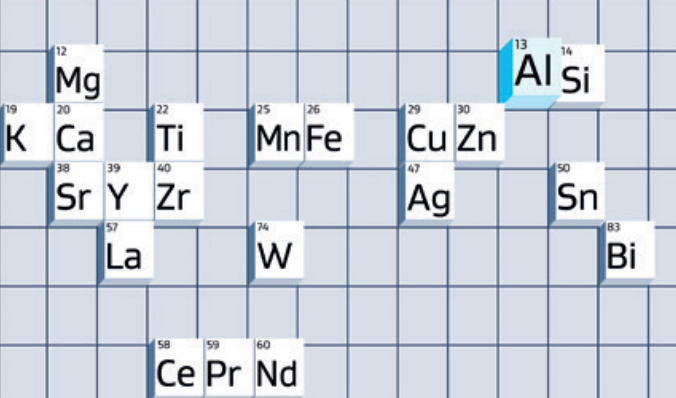

List of doped elements

Another example is the silicon-aluminum composite material, which, contrary to hydrotalcite, is suitable for applications requiring even lower surface acidity than pure alumina, such as diesel engine catalysts. Additionally, Sasol offers highly flexible doped alumina and ultra-high-purity alumina (5N+) among its product range.

Product Details

Chemical Properties

|

Product |

Purity |

Main impurities(ppm) |

|||||||||||

|

Na |

Si |

Fe |

Ca |

Mg |

Ga |

Cr |

Ni |

Ti |

Cu |

Zn |

Zr |

||

|

APA-0.5 |

99.96% |

10 |

60 |

100 |

10 |

30 |

55 |

5 |

5 |

30 |

<1 |

45 |

5 |

|

APA-0.5 with Mgo |

99.96% |

10 |

60 |

100 |

10 |

300 |

55 |

5 |

5 |

30 |

<1 |

45 |

5 |

|

AHPA-0.5 with Mgo |

99.995% |

5 |

15 |

10 |

5 |

300 |

<1 |

<1 |

<1 |

<1 |

<1 |

2 |

2 |

|

APA-RTP-SB |

99.96% |

10 |

60 |

100 |

10 |

300 |

55 |

5 |

5 |

30 |

<1 |

45 |

5 |

|

AHPA-RTP-SB |

99.995% |

5 |

15 |

10 |

5 |

300 |

<1 |

<1 |

<1 |

<1 |

<1 |

2 |

2 |

|

UHPA-Alpha-Milled |

99.998% |

1 |

5 |

2 |

1 |

<1 |

<1 |

<1 |

<1 |

<1 |

<1 |

<1 |

<1 |

|

UHPA – Alpha |

>99.999% |

<1 |

2 |

1 |

<1 |

|

|

|

|

<1 |

|

|

|

|

TSA 200 / 20 |

99.7% |

10 |

140 |

10 |

10 |

|

|

|

|

1200 |

|

|

|

Physical Properties

|

Product |

Particle Size(μm) |

Surface Area |

Green Density |

Fired Density |

Bulk Density |

||

|

D10 |

D50 |

D90 |

(㎡/g) |

(g/cc) |

(g/cc) |

(g/l) |

|

|

APA-0.5 |

0.2 |

0.3 |

0.4 |

7.5 |

2.22 |

3.94 |

|

|

APA-0.5 with Mgo |

0.2 |

0.3 |

0.4 |

7.5 |

2.22 |

3.96 |

|

|

AHPA-0.5 with Mgo |

0.2 |

0.3 |

0.4 |

8.0 |

2.22 |

3.96 |

|

|

AHPA-RTP-SB |

25 |

60 |

125 |

7.5 |

2.4 |

3.95 |

|

|

AHPA-RTP-SB |

25 |

60 |

125 |

7.5 |

2.4 |

3.95 |

|

|

UHPA-Alpha-Milled |

0.1 |

<1 |

10 |

8 |

2 |

|

950 |

|

UHPA – Alpha |

|

35 |

|

5 |

|

|

|

|

TSA 200 / 20 |

|

0.5 |

|

200 |

|

|

|

Conclusion

Pseudo-boehmite was initially developed for the petrochemical industry but has since found applications in polishing, chromatography, adsorption, gas separation, and more, contributing to the expansion of the "SB" powder moniker into numerous industries. Sasol's mastery of the alkoxide hydrolysis process has endowed it with the capability to diversify into composite materials and other high-purity metal oxide materials. This demonstrates the power of understanding one process thoroughly, enabling the company to apply that knowledge broadly and effectively in multiple areas. In essence, it embodies the principle of "learning one thing and applying it to many," a testament to its prowess.

Related News