TOSOH Zirconia Powders

Product Number:

0312121

Features

Using the latest hydrolysis processes and nano-technologies, Tosoh produces the TZ-Series of zirconia powders. Through complete control over materials and production processes, Tosoh can maintain consistent high purity and quality. The TZ-Series* is the ultimate zirconia powder that delivers added value and product improvements to the customer.

Contact Us

Product Details

| LEGEND FOR GRADE NAMES | |||||

| < Example > | |||||

| TZ | 3Y | S | 20A | B | -E |

| I | II | III | IV | V | |

| I: | mol % of yttria, where "3Y" would be 3 mol% Y2O3 | ||||

| II: | "S" for easy moldability grades | ||||

| III: | ATZ grades, where "20A" would be 20 wt% alumina | ||||

| IV: | binder grades, where "B" would be binder 3% grades, and "BC" would be binder 5% grades | ||||

| V: | "E" for easy sintering grades | ||||

| Basic Grades | |

| TZ-3Y-E, TZ-3YB-E | |

| Partially-stabilized zirconia powder with uniform dispersion of 3 mol % yttria. TZ-3Y-E exhibits superior sintering properties and higher aging resistance at a lower sintering temperature of 1300ºC. Sintered bodies produced with TZ-3Y-E show a fine crystal grain structure resulting in greater improvements in strength, fracture toughness, as well as resistance to wear and aging. TZ-3Y-E has numerous applications including materials for industrial parts and everyday products. | |

| POWDER CHARACTERISTICS | TZ-3Y-E, TZ-3YB-E |

| Y2O3 (mol%) | 3 |

| Actual Partical Size (µm) | 0.04 (40nm) |

| Y2O3 (wt%) | 5.2 ± 0.5 |

| HfO2 (wt %) | < 5.0 |

| Al2O3 (wt %) | 0.1 ~ 0.4 |

| SiO2 (wt %) | ≦ 0.02 |

| Fe2O3 (wt %) | ≦ 0.01 |

| Na2O (wt %) | ≦ 0.04 |

| Pigment (wt %) | - |

| Specific Surface Area (m2/g) | 16 ± 3 |

| S Grades | |

| TZ-3YS-E, TZ-3YSB-E, TZ-3YSB-C | |

| S grades have a smaller surface area that contributes to a smooth flow for the compound or slurry in injection molding, tape casting, and other molding methods. S grades are highly recommended for producing large parts by a mechanical press or CIP. | |

| POWDER CHARACTERISTICS | TZ-3YS-E, TZ-3YSB-E, TZ-3YSB-C |

| Y2O3 (mol%) | |

| Actual Partical Size (µm) | 0.09 (90nm) |

| Y2O3 (wt%) | 5.2 ± 0.5 |

| HfO2 (wt %) | < 5. |

| Al2O3 (wt %) | ≦ 0.1 ~ 0.4 |

| SiO2 (wt %) | ≦ 0.02 |

| Fe2O3 (wt %) | ≦ 0.01 |

| Na2O (wt %) | ≦ 0.06 |

| Pigment (wt %) | - |

| Specific Surface Area (m2/g) | 7 ± 2 |

| High Translucent Grades | |

| Zpex® & Zpex® Smile | |

| Dental restorations with the natural look and feel of real teeth can be produced with Zpex. | |

| High all light transmittance in addition to superior hydrothermal aging resistance. | |

| Translucency | |

|

|

| Aging Property (140ºC in water x 25 hr) | |

|

|

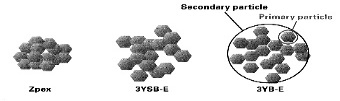

| High all light transmittance by improving the aggregation of particles | |

|

|

| pex (left) and TZ-3YSB-E. (right) | |

|

|

| POWDER CHARACTERISTICS | Zpex |

| Y2O3 (mol%) | 3 |

| Actual Partical Size (µm) | 0.04 (40nm) |

| Y2O3 (wt%) | 5.35 ± 0.2 |

| HfO2 (wt %) | < 5.0 |

| Al2O3 (wt %) | ≦ 0.1 |

| SiO2 (wt %) | ≦ 0.02 |

| Fe2O3 (wt %) | ≦ 0.01 |

| Na2O (wt %) | ≦ 0.04 |

| Pigment (wt %) | - |

| Specific Surface Area (m2/g) | 13 ± 3 |

| TYPICAL PROPERTIES OF SINTERED BODY | |

| Density (g/cm3) | 6.08 |

| Bending Strength R.T. (MPa)*1 | 1,100 |

| Hardness (Hv 10)*2 | 1,250 |

| *1: JIS R1601 (3-point bending test) | |

| *2: JIS R1610 (loads: 98.07N) | |

| *Above is typical data and not guaranteed | |

| Fully Stabilized Grades | |||

| High-purity Tosoh powder provides sintered bodies which have superior electric properties. | |||

| Tosoh powder has superior sintering properties and provides sintered bodies which have uniform grains. | |||

| POWDER CHARACTERISTICS | TZ-8Y | TZ-8YS | TZ-10YS |

| Y2O3 (mol%) | 8 | 8 | 10 |

| Specific Surface Area (m2/g) | 16±3 | 7±2 | 6±2 |

| Binder (Approx. wt%) | - | ||

| Appearance | Granule | Granule | Granule |

| TYPICAL PROPERTIES OF SINTERED BODY | TZ-8Y | TZ-8YS | TZ-10YS |

| Density (g/cm3) | 5.9 | 5.80 | |

| Bending Strength R.T. (MPa)*1 | 300 | 200 | |

| Hardness (Hv 10)*2 | 1,250 | ||

| Electric Resistance (Ω·cm) at 800ºC*3 | 19.8 | 20.3 | 27.3 |

| Electric Conductivity logσ(S/cm) at 800ºC*3 | -1.30 | -1.31 | -1.44 |

| *1: JIS R1601 (3-point bending test) | |||

| *2: JIS R1610 (Loads: 98.07N) | |||

| *3 : 4-terminal method by direct current | |||

| *Above is typical data and not guaranteed. | |||

| ATZ Grades | ||||

| ATZ Grades "A" | ||||

| "A" grades contain uniformly dispersed 3 mol % yttria, 20 wt% alumina, and exhibit extremely high mechanical strength after HIPing. This grade is most commonly used to produce industrial parts in high strength, high water resistance applications. | ||||

| POWDER CHARACTERISTICS | TZ-3Y20A | TZ-3Y20AB | TZ-3YS20A | TZ-3YS20AB |

| Y2O3 (mol%) | 3 | |||

| Specific Surface Area (m2/g) | 15±3 | 7±2 | ||

| Binder (Approx. wt%) | - | 3 | - | 3 |

| Appearance | Granule | Granule | ||

| TYPICAL PROPERTIES OF SINTERED BODY | TZ-3Y20A | TZ-3Y20AB | TZ-3YS20A | TZ-3YS20AB |

| Density (g/cm3) | 5.5 | |||

| Bending Strength R.T. (MPa)*1 | 2,000 | |||

| Hardness (Hv 10)*2 | 1,400 | |||

| *1: JIS R1601 (3-point bending test) | ||||

| *2 : JIS R1610 (Loads: 98.07N) | ||||

| *Above is typical data and not guaranteed. | ||||

Related Products

undefined

Product Message

We can recommend suitable products for you according to your needs, please fill in the following form and we will contact you in time!